Articles & Excerpts

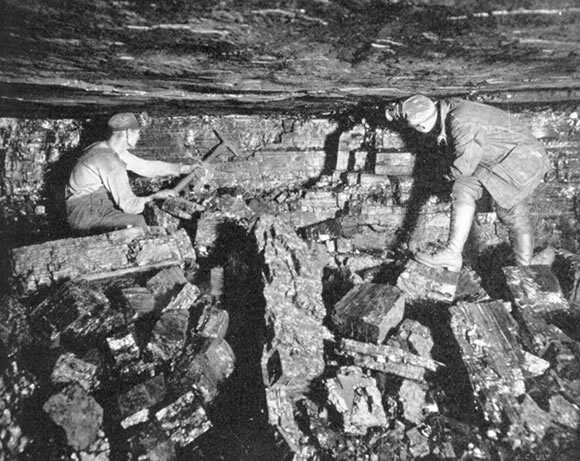

This photo was taken around 1919 in the Twin Mine in the Twinton area of Overton County. The Wilder Seam is about five feet thick near Twin and was productive for over 50 years. Much of the coal mined in Putnam, Overton, and Fentress Counties, Tennessee has been from the Wilder Seam. (Photo from The Coal Reserves of Tennessee by Edward Luther)

The Overton / Fentress / Putnam Mining Chronicles

September 24, 1998

By Jason Duke

Not many people remember the sound of steam engines rumbling through Monterey, Crawford, Twinton, and Wilder. Those that do have stories to tell of a time that may soon be forgotten if we fail to properly preserve that rich history. It was not that long ago that small cities bustled with activity and electric lights on the Cumberland Plateau. The cities we are talking about are not Cookeville or Crossville or the booming Upper Cumberland cities of today. Instead, they were Crawford, Twinton (Twin or Twin City), Cooktown, Cravenstown, Davidson, Highland Junction, Wilder, and Monterey.

What was the source of all this activity? Why did some people have electricity in Crawford, Twinton, and Wilder thirty to forty years before other parts of Overton, Fentress, and Putnam Counties? The answer to these questions are the coal mines and railroad. The mines attracted thousands of people to the plateau region via the new railroad. Trains that ran as early as 1901 brought mail and other goods from Nashville into the previously unreachable areas of Overton and Fentress Counties. Active mining production in the area began in 1901 in Overton County. Mining had been conducted as early as 1850 in Fentress County, but the lack of suitable transportation to markets kept mining from commercializing until after 1900. The coal shipped from Overton, Fentress, and Putnam Counties would help fuel the nation's industries through two World Wars and the Korean War. The same coal would also be used to help TVA provide electricity to rural areas in the Southeast. That coal also heated homes, churches, businesses, and schools throughout the area and the state.

Coal mining and its benefit to our way of life today can easily be seen. What is more difficult to see are the many people who ran the mines, commissaries, hotels, and mined the coal. Many people risked their lives daily by simply going to work. In today's modern society, very few of us can comprehend what it mentally takes to go to work in a world of darkness without the guarantee of ever seeing the sun or your family again. In the following weeks, I will begin to chronicle the histories and stories of these brave people as well as the communities in which they lived.

If you ever worked in the mines or in a related area such as commissaries, mining area hotels, etc. and would care to share your story, I would like to hear about it. Also, if you have any mining photographs or memorabilia from the era, I can copy them at your residence with a computer scanner to be included in the book. Any materials used will be promptly returned as they have in the past by me. Mining scrip, maps, and other materials are also useful. Even just one old photo means a lot. Please share them so they can be enjoyed by others.

Five years ago, I began to research the history of coal mining in Overton County. My research quickly grew to encompass Fentress and Putnam County mining as well. What was once two or three pages has now grew to hundreds of pages and is becoming a book that will be called The History of Coal Mining in Overton, Fentress, and Putnam Counties, Tennessee. This book will be placed in the libraries of the schools and communities in the area. It will also be printed and sold to the public for the cost of reproduction only. The book will contain photos and stories of mining and railroading from 1850 until about 1968. Over forty pictures have been copied thus far and more will be copied soon.

Contact Jason Duke at 931-823-8616 and please leave a message if there is not an answer. My mailing address is 266 Duke Lane, Livingston, TN 38570. All photos and materials will be returned promptly.

John Ledbetter, Uncle to Theb Garrett, outside of one of the Wilder openings about 1934. Photo courtesy of Theb Garrett.

The Overton / Fentress Mining Chronicles

April 16, 1998

By Jason Duke

Many articles have been written over the years about the history of the coal mining industry in the Upper Cumberlands. From those, one can learn a lot about the mines and the towns, as well as the difficult times faced by many residents. Equally as important as the histories of the industry are the stories of the thousands of individuals who labored in the mines. Many of my articles will feature them and highlight their contributions to mining in the area. The first of these articles features Thelbert (Theb) Garrett of the Hanging Limb community in Overton County.

Theb Garrett was born May 2, 1926, son of Tom Garrett, a miner in Wilder. Many of Theb's relatives made a living working in the mines. Work was not plentiful outside of the mines on the Cumberland Plateau except for farming or in the few rock quarries or sawmills in the area. He started his 13-year career in mining at the Cub Mountain Coal Company at the age of 18 in 1944. For three years, Theb worked at loading coal and assisting in the mine. World War II had once again brought some form of prosperity to the area mines that had suffered so greatly during the Depression years. In 1947, Theb moved on to the Buckeye Coal Company located at the top of Cub Mountain on the Twin side. He remembers the Buckeye area being a small community with a store and several houses around.

The Buckeye mine was like most of the mines in Overton and Fentress County by being a drift mine. A drift mine enters the side of a mountain or slope at a relatively flat angle and remains horizontal, following the coal seam. The best producing seam in Overton and Fentress County is the Wilder Seam, with most of the coal being about 180 feet beneath the surface of the plateau. Drift mines were the prominent choice for mining up until the 1950's and could be found in nearly every hollow in coal country.

Theb opened a small mine with his father-in-law, Tommy Looper, in 1949 and continued to operate it until he got a job with the Allred and Brown Coal Company for 1952 and 1953. In 1954 and 1955, Theb worked in what were called morse camps over in Fentress County. Morse camps were old mines where the person that owned the mineral rights allowed anyone that wanted to mine the remaining coal and pay a royalty per ton. The Gernt family owned the rights to the mines that Theb worked in near Wilder.

Wilder was playing out in the 1950's. Fentress Coal and Coke had pulled out all of its Wilder operations and had moved on to Monterey in Putnam County, hoping to get some production out of its mine there. Theb's last job in the mines was with Mountain Land Products from 1955-1957. It was then that he had to "retire" from the mines after developing Black Lung, which most miners developed after years of breathing coal dust. Black Lung can develop in as little as 10 years, and many people that never worked in the mines, but lived near them, developed it from breathing the thick sulfur smoke and coal dust in mining towns.

Theb's memories of mining are pleasant in that he would still rather work in the mines than anywhere else he has worked in his life. He admitted that it was somewhat dirty and nasty but he really enjoyed the work. Most of the coal Theb would haul from the mines was mine run (egg, lump, stoker, and block mixed together). The Love and Amos Coal Company of Nashville would buy most of the coal from the small mines in the area at that time for $3 to $5 per ton. Theb worked in seams as thick as 6 feet in places on Cub Mountain and some as thin as 32 inches.

Theb noted that Hanging Limb and Crawford capitalized on the coal industry by each having a hotel for the travelers riding the "jitney" passenger train through the towns. Crawford had rows of section houses that miners and non-miners owned or rented. Numerous stores were throughout the area as the areas surrounding the mines themselves prospered when the mines did.

The author wishes to thank Theb, his daughter Joyce, and the rest of his family for all of the help they provided.

As always, if anyone has any photos or mining information they can share, please contact me. I am always interested in interviewing miners and their families and would like to include all stories and photos possible in the History of Coal Mining in Overton and Fentress Counties book I am writing. Even just a photo, old map, or piece of scrip helps. Contact Jason Duke at 931-823-8616 and please leave a message if there is not an answer. My mailing address is 266 Duke Lane, Livingston, TN 38570. All photos and materials will be returned promptly.

Jonathan Allred in the machine shop at the ABC Mines in Monterey in 1949. He is talking to one of the miners down in the mine. |

The tipple that Jonathan constructed at Monterey in 1947. The hole in the ramp leading to the tipple was for removing rocks from the coal. |

The Overton / Fentress Mining Chronicles

April 23, 1998

By Jason Duke

One of the most popular former mine operators living today is eighty-seven-year-old Jonathan Allred of Crawford, TN. His mining career spanned 30 years from 1937 to 1967. Jonathan is well respected by all that have worked for him and know him. His contributions to the mining industry over the years are apparent from the discussions one has with anyone living in the area.

Jonathan got his start in mining by opening a mine on Bear Knob in Overton County, near the top of Cub Mountain. Getting to the mine was no easy job, and he constructed a one-mile road over the rough terrain over to the newer Highway 85 (it was then) that goes up Cub Mountain to Twinton from Allred. A tipple also had to be constructed, and a long chute was made to run coal down into the tipple. Since he was just getting started in mining, Jonathan had to settle for bar screens instead of the better shaker screens for sorting coal.

Tipples were necessary for virtually every mine. The purpose of a tipple is to provide a place for the loading of coal into either railroad cars or into large dump trucks. A good tipple was one of a mine's biggest assets. For instance, during the Wilder Strike of 1932-1933, one of the more noteworthy events was the burning of the tipple at the Patterson Brothers' mine at Davidson. The tipple was worth $20,000 dollars in 1932 (about $250,000 today). It is almost impossible to load coal without a tipple and the loss of one would shut a mine down.

Shaker screens were used for sorting coal. Coal came out of the mines in what was called mine run and consisted of all sizes of coal. The different types of coal are: block (lump) – 6 inch blocks and up, egg – 3 to 6 inch blocks of coal, nut – 1 ½ to 3 inch blocks of coal, stoker – ¾ to 1 ½ inch blocks of coal, and steam – ¾ inch and smaller blocks of coal.

Jonathan also did some work in the old Brier Hill Colleries mines at Twinton with Alvin Owens in 1938. He never got much production out of the Bear Knob mine, so he closed it in 1939 and partnered with W. Burris (W.B) Brown to form the A&B Coal Company. They opened their mine in the hollow off to the right of Highway 85 as you get to the top of the plateau on Cub Mountain. The mine works were extensive enough at A&B that they cut back into the old Brier Hill Colleries Crawford mines and hit bad air. Jonathan remembers the situation as "When you hit bad air, an open flame will start to smoke a bit. When it started doing that, you had better get to backing up and getting out of it. After that, your knees would start to get weak and a man could lose consciousness."

At A&B, they did a lot of robbing in the old mine works. In large rooms, they would pull three or four pillars on each side along with the entry stumps until they got a fall. This was extremely dangerous work, but very rewarding since these were prior-mined areas with five- and six-foot coal seams. Cave-ins happened frequently in the old mine works. "If you've never been in the mines, then you can't imagine the feeling you get when the timbers start cracking and you hear this low thunder and see the cap boards start cutting and ripping. You had either better get moving out or get behind a pillar of coal if you can't. A fall always caused a right smart wind because nearly all of them broke clean to the surface, 180 feet up." Jonathan always said "Coal mining wasn't any safer than the people that worked in them".

When the Brier Hill Colleries went bankrupt in the 1930s, A&B bought about 2800 acres with 41 houses at Twinton, which they later sold. Jonathan remembers that Fentress Coal & Coke (Wilder) only had about 9,100 acres of land and the Brier Hill Colleries (Crawford and Twinton) had over 100,000 acres.

In 1947, A&B drilled nine test holes about five miles east of Monterey near Meadow Creek into a six-foot seam of coal. They put in a slope mine that was on a 16-degree angle that went into a 16-foot-wide shaft. New partners were added to the company to make the name the ABC Coal Company. Jonathan's brother Bud Allred and his brother-in-law H. Gentry Copeland joined him and W.B. Brown. The Monterey mine was a huge success and was sold to Bill Turner Ray in October 1954. Bill Turner Ray later sold the mine to the Blue Diamond Coal Company, who ran the mine until their TVA contract expired, leaving approximately 10 million tons still in the ground there.

From there, Jonathan worked with the Love & Amos Coal Company of Nashville and bought coal from local mines and inspected them for the company to ensure that they could produce a certain tonnage. Coil Copeland and Jonathan bought Mr. Amos out and started shipping the coal from the 18 local mines still operating to TVA in 1957 and 1958. From 1960 to 1962, Jonathan worked for a coal company he was part owner in on the Cumberland River in East Kentucky near Balkan, Pineville, and Harlan. He finished his mining career by returning to Overton County to build tipples for local mines until the railroad ceased operation about 1967.

As always, if anyone has any photos or mining information they can share, please contact me. I am always interested in interviewing miners and their families and would like to include all stories and photos possible in the History of Coal Mining in Overton and Fentress Counties book I am writing. Even just a photo, old map, or piece of scrip helps. Contact Jason Duke at 931-823-8616 and please leave a message if there is not an answer. My mailing address is 266 Duke Lane, Livingston, TN 38570. All photos and materials will be returned promptly.

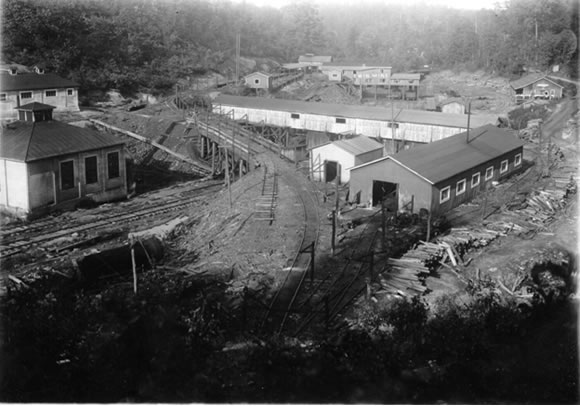

This photo was taken of the Brier Hill Colleries Twin Mine in 1919. Approximately 300 people were

employed by this mine. At the front left is the powerhouse. Behind it is the bathhouse. The building with Twin Mine painted on it houses the automatic tipples. The long building in the center of the picture houses the other tipples. The two buildings in the front right comprise the machine shop. Gentry Copeland’s father once worked in these buildings. The long row of timbers were used for roof supports in the mine. At the back right is the commissary. If you look closely, you will notice a row of men in white shirts standing in front of the commissary. This mine was located just north of present-day Twinton on the road to Cravenstown.

(Photo courtesy of June Evans)

The Overton / Fentress Mining Chronicles

April 30, 1998

By Jason Duke

In order to help understand the history of mining in Overton and Fentress Counties, it helps to first know a little about the history of the area. This article will detail some of the early history with more to follow in the future. Next week will feature the story of another former miner from the area. Please continue to call me if you or someone you know ever mined in the area so you can be included as well.

Overton County lies on the northwestern side of the Northern Tennessee Coal Field. It is bordered on the east by Fentress County, on the south by Putnam County, on the west by Jackson County, and on the north by Clay and Pickett Counties. The county contains 277,312 acres, or about 433 square miles. This region is characterized by a bold, rugged mountain topography, having an altitude range of 700 to 2,000 feet. About two-thirds of the county lies on the Highland Rim, with the other third of the county lying on the Cumberland Plateau. The northwestern portion of the county lies on the Highland Rim. It is a broad, gently rolling plain, and has an altitude varying from 900 to 1,000 feet. The plain is often broken by low, rolling hills.

All drainage in the county is toward the Cumberland River, which lies several miles to the west of the county. The main rivers and streams draining the county are the Roaring River, West Fork Obey River, East Fork Obey River, Spring Creek, Big Eagle Creek, Mill Creek, and Mitchell Creek.

A permanent settlement in Overton County was first established in 1800 at Hilham. Some settlements closer to present-day Livingston had also occurred, but their exact date is not known. Hunters had been passing through the area for several years before the first settlement had been made. The county officially organized in 1806. The county seat was established at Monroe in 1810 and moved to Livingston, the present-day county seat, in 1835.

Overton County was prosperous in its early years and compared favorably with other sections of the state up to the era of railroad construction in the 1860's. Railroads favored the more level areas of the state and tended to avoid the hilly, mountainous terrain of Overton County. This brought about a slow retrogression that lasted up to about 1900. The first railroad entered the county from Monterey to Crawford in 1901. In 1906, the Overton County Railroad was built from Algood to Livingston and gave Livingston a market for its goods. The Algood-Livingston line was pulled up in the 1960's when the demand for the railroad diminished. The Monterey-Crawford-Wilder line suffered the same fate in the 1960's, too. No railroads operate in Overton County today.

Overton County has a mild, pleasant climate and seldom experiences very hot or very cold temperatures. The summer months have warm days and cool nights. Some snow falls in winter, but it never remains on the ground for more than a week. The average yearly temperature is about 57 degrees Fahrenheit and the average yearly rainfall is about 50 inches.

The coal field area of Overton County is confined to the southeastern part of the county. The largest area of recoverable coal is on a long spur of the plateau that projects northward out of the main mass between the East and West Fork Obey rivers. It is estimated that approximately 54 square miles of Overton County is underlain by mineable coal. Eleven named coal seams are known to exist in Overton County, but only two of them have known recoverable reserves. The two seams of importance are the Wilder seam and the Sewanee seam.

Overton County contains approximately 12,854,000 tons of known recoverable coal reserves. The Wilder seam contains 12,451,00 tons of recoverable coal in Overton County, and the Sewanee seam contains 403,000 tons of recoverable coal. The Wilder coal is contained in the upper part of the Signal Point shale, underneath the Sewanee conglomerate. The Wilder coal is near the middle of the Fentress formation.

The Sewanee coal is contained in the Whitwell shale. This coal lies above the Sewanee conglomerate. It is typically found 20 to 40 feet above the Wilder coal. All known reserves of the Sewanee coal in Overton County are less than 42 inches in thickness and have not yet been mined on a large scale.

The Tennessee Central Railroad completed a branch from Monterey to Crawford in 1901 and from Crawford to Wilder in 1903. This opened the area up for the shipping of coal and timber. Few roads existed in the area up until this time and none of the streams were suitable for barges. The effects of the railroad were clearly displayed on Overton County's total coal production. Overton County reported 680 tons of coal produced in 1901, 3,447 tons were reported for 1902, and production for 1903 was reported at 84,930 tons. It is not known for sure if the 1901 coal was mined at Obey City, then known as Cliff Springs, or at Crawford.

The Brier Hill Collieries, formerly the Crawford Coal and Iron Company, began operations in 1902 when they opened Mine Number 1 at Crawford. Mine Number 2 opened at Crawford in 1903. The Obey River Coal Company, also known as the Peacock Coal and Coke Company, got started about 1902. In 1905, the Tennessee Central Railroad built a railway bridge to reach a mine on the east side of the East Fork Obey River. As of 1925 those mines had been productive, but no large operations had developed. Mining activities remained mainly in the Crawford area for several years after 1903. The Brier Hill Collieries opened the Laurel Creek Mine in 1909 and the Overton mine opened near Davidson in 1910. The largest mines in Overton County were opened by the Brier Hill Collieries in the Twin City, now Twinton, area about 1919. These mines were named Twin, Laurel, and Baker. The Laurel mine is the one that opened in 1909. The Crawford Mining Company mine near Crawford was also one of the largest mines in Overton County.

The Twin mine of the Brier Hill Collieries contained some of the most productive coal seams ever mined in Overton County. Average thickness was around five feet, and in one room it was six feet. The thinnest coal found in the mines was still four-and-a-half feet thick. The roof of the Twin mines was a sandy shale and locally became a sandstone in spots. This allowed for excellent mining conditions and required few timbers to be set for roof supports. Some of the smaller mines in Overton County in the Wilder seam were Obey City No. 1, No. 2, No. 3, No. 4, the Paul Farmer mines near Obey City, mines on Looper Branch, the Curtis Vaughn Coal Company Mines on Bill Branch, and mines on Little Laurel Creek.

As always, if anyone has any photos or mining information they can share, please contact me. I am always interested in interviewing miners and their families and would like to include all stories and photos possible in the History of Coal Mining in Overton and Fentress Counties book I am writing. Even just a photo, old map, or piece of scrip helps. Contact Jason Duke at 931-823-8616 and please leave a message if there is not an answer. My mailing address is 266 Duke Lane, Livingston, TN 38570. All photos and materials will be returned promptly.

This photo was taken in 1919 across from the entrance to Old Baker – Laurel Creek # 8 mine. The mine was about two miles southeast of Crawford, down in the hollow below Windletown and Tiptown on Big Laurel Creek. Gentry Copeland is at left center. His sister, Doshia Lee Copeland, is at top. His aunt, Nellie Copeland is at top right. His uncle, Herb Copeland, is at right center. His aunt, Noel Copeland, is at bottom left. Brier Hill Colleries ran the Laurel Creek mines. (Photo courtesy of Gentry Copeland)

Maywood Sisco runs a tram motor out of the Twin Mine about 1928, in their heyday. This was taken near the machine shop and the #3 Cuba entrance. Notice the electric trolley wire above the tram. Twin generated electricity until 1932 using the Brier Hill Colleries steam generator. (Photo courtesy of Gentry Copeland)

The Overton / Fentress Mining Chronicles

May 7, 1998

By Jason Duke

In order to help gain a better understanding of how the mines in Overton and Fentress County operated, several personal interviews were conducted with Gentry Copeland. Gentry is 83 years old and currently lives in the Alpine area. His career in the mines started in 1934 and lasted until 1968. His experience and knowledge of the area truly qualify him as an expert on Overton County mining. There will be several articles that will recount Gentry's memories of Overton County mining and tell some interesting facts about the area.

Gentry was born and raised in the Crawford area when mining was the key industry. His father worked in the mines for years, including the Brier Hill Collieries mines in the Crawford and Twinton area. Gentry recalls that life in Crawford was centered around the mines and the railroad. The railroad brought life to the area and also brought in the outside world. Gentry reported that "trains hauled heading lumber, handle lumber, shuttle lumber, building lumber, tannin bark, acid wood, coal, and made two passenger runs at from Monterey to Wilder." He was amazed that the trains managed to haul as much as they did and still carry coal as their principal cargo. The railroad also used to run from Twinton up to Cravenstown. At Cravenstown, it became a narrow gauge and went north to Cooktown and then north off of the plateau and down to Riverton on the East Fork Obey River in Fentress County.

Gentry got his start in mining in 1934 by helping Alvin Owens and Lark Gunter at Twinton Old No. 2 mine working in four to five feet of coal. (The reason that mines are being referred to as Old Twin No. 2, etc., is that the Brier Hill Colleries of New York shut down the Twin mines indefinitely in 1932.) They spent the majority of their time converting the mines from car mines to truck mines. When the Brier Hill Collieries shut down, so did electric power. All of the electric power in the mines of the area had been produced by steam generators operated by the Collieries. When the Collieries declared bankruptcy, the electric generators were disassembled and sold. The Tennessee Valley Authority did not supply electric power to this area until after 1946, when the first line was ran from Norris Dam to Wilder. Mining in Overton County suffered through a regression period after the Wilder Strike of 1932-1933. Rising labor costs and falling coal prices shut the Brier Hill Collieries down and crippled the Fentress Coal and Coke Company to the east.

With no electric power in the abandoned mines, a lot of changes had to be made. The former method of extracting coal from the mines had been with tram motors that pulled bottom-dumping cars out of the mines. The bottom would "fall out" of the cars as they passed over the tipple for the collection of the coal and its concurrent loading into railway cars. The absence of electricity necessitated that end-dumping cars be used with the mules that replaced the electric tram motors. The mules were not nearly as fast nor as strong as electric tram motors. The result was decreased production, not only because of the use of mules but also because of the fact that these mines were being reworked and were not new discoveries.

Gentry had his first experiences with "black damp" and "stink damp" in the Old Brier Hill Collieries Twinton No. 2 mine. When old mines were reworked, air problems were common due to poor circulation. Without electricity, the massive fans that once circulated vast amounts of air through the mines were no longer used. "Black damp" involved large amounts of carbon dioxide in the air. After coal was blasted, large amounts of oxygen were depleted from the air and carbon dioxide rushed in to replace it. "Black damp" was capable of killing a man. "Stink damp" also occurred after blasting sometimes. It involved large amounts of sulfur dioxide replacing the oxygen after blasting. The Wilder coal seam is high in sulfur and "stink damp" was a common problem. Good ventilation and more modern blasting techniques helped to eliminate this problem.

From 1941-1947, Gentry served as operator for the Brown and Winningham mines. From 1947-1951, he was the foreman at ABC (Allred, Brown, and Copeland) mines in Monterey. From 1951-1952, he operated the Allred and Brown Coal Company and from 1952-1968, Gentry went out on his own and operated the H. Gentry Copeland Coal Company.

Gentry has experienced nearly everything that can happen in the mines. His main accomplishment is that no one was ever killed in any of the mines he was in charge of. Safety was big to Gentry, and he is thankful that luck often looked his way. A good safety factor was also the stability of the mine's roof. The number of timbers used for roof support was directly proportional to the geologic properties of the rock above the coal. Gentry believes that "you need a timber to bump your head on and one to bump your behind on."

Gentry, like all mine operators in the area, sold five types of coal. They were: block (lump) coal - 6 inch blocks and up, egg coal - 3 to 6 inch blocks of coal, nut coal - 1 ½ to 3 inch blocks of coal, stoker coal - ¾ to 1 ½ inch blocks of coal, and steam coal - ¾ inch and smaller pieces of coal.

The top seller was steam coal, which was desired by industry. The DuPont - Old Hickory, TN plant was a large purchaser of Overton and Fentress County Coal from the 1920's up to 1944. After 1944, DuPont purchased much of its coal from Western Kentucky coal companies. The Tennessee Valley Authority (TVA) was the primary purchaser of steam coal in the 1950's and 1960's from Gentry. The majority of coal sold to TVA went to Kingston to be burned in the Kingston Steam Plant. As of 1960, the Kingston plant was the largest and one of the most efficient steam plants in the world, and could burn about 4.5 million tons of coal per year. The Widows Creek plant burned about 4 million tons per year and the Watts Bar and Hales Bar plants were also large purchasers of Overton and Fentress County coal. Alcoa Aluminum had a steam plant that helped supply electric power to Oak Ridge in its "secret days" during World War II. Gentry continuously sold 300-500 tons per day to Alcoa during the war. World War II helped to modernize the coal industry once again in the area. Donald P. Nelson, Head War Production Chief, often received calls for assistance from Gentry concerning problems in the mines. Nelson made sure that Gentry had good equipment and even prodded Dempster Dumpster in Knoxville once to get him an underbody hoist on a Jimmy truck for coal hauling. Gentry has many fond memories of mining in Overton County, and it is the author's hope that they are not forgotten and can be appreciated by others.

As always, if anyone has any photos or mining information they can share, please contact me. I am always interested in interviewing miners and their families and would like to include all stories and photos possible in the History of Coal Mining in Overton and Fentress Counties book I am writing. Even just a photo, old map, or piece of scrip helps. Contact Jason Duke at 931-823-8616 and please leave a message if there is not an answer. My mailing address is 266 Duke Lane, Livingston, TN 38570. All photos and materials will be returned promptly.